Categories

Contact Us

E-mail :

hbzx@gasequipment.com.cn

E-mail :

ales@gasequipment.com.cn

Phone/WhatsApp/Wechat:

+86-15810525255

Address:

East of Fenghuang Road, Nangong City, Xingtai City, Hebei Province, China

Low temperature liquid filling pump

We Support Customized Services

Regardless Of Material And Model Please Tell Me Your Needs

- 产品描述

- 符合标准

-

Introduce

Low temperature liquid filling pump is a special type of pump equipment specifically designed to transport low-temperature liquids and pressurize them to meet filling requirements. Mainly used in gas stations, petroleum, air separation, chemical and other industries, it is used for the filling of industrial low-temperature liquids such as LNG, liquid oxygen, liquid nitrogen, liquid argon, liquid hydrocarbons, liquefied natural gas, etc. It transports low-temperature liquids from low-pressure places such as storage tanks to high-pressure filling containers or pipelines.

Working principle

● Reciprocating low-temperature liquid filling pump: relies on the reciprocating motion of the piston (plunger) in the working chamber of the liquid cylinder to achieve suction and discharge. When the piston moves to the right, the volume of the pump cylinder increases, the pressure decreases, the liquid pressure in the inlet pipe is greater than the pressure inside the pump cylinder, the suction valve opens, and the liquid flows into the pump cylinder. When the piston moves to the left, the pump cylinder volume decreases and the liquid pressure rapidly increases. When the pressure rises to the point where the discharge valve can be opened, high-pressure liquid is discharged through the discharge valve.

● Centrifugal low-temperature liquid filling pump: relies on the rotating impeller to do work on the liquid. When the pump is filled with liquid, the impeller rotates at high speed, and the liquid generates centrifugal force under the action of the impeller, flowing from the inlet to the outlet of the impeller. The pressure energy and velocity energy increase, and the velocity energy is further converted into pressure energy in the diffuser chamber before being output.

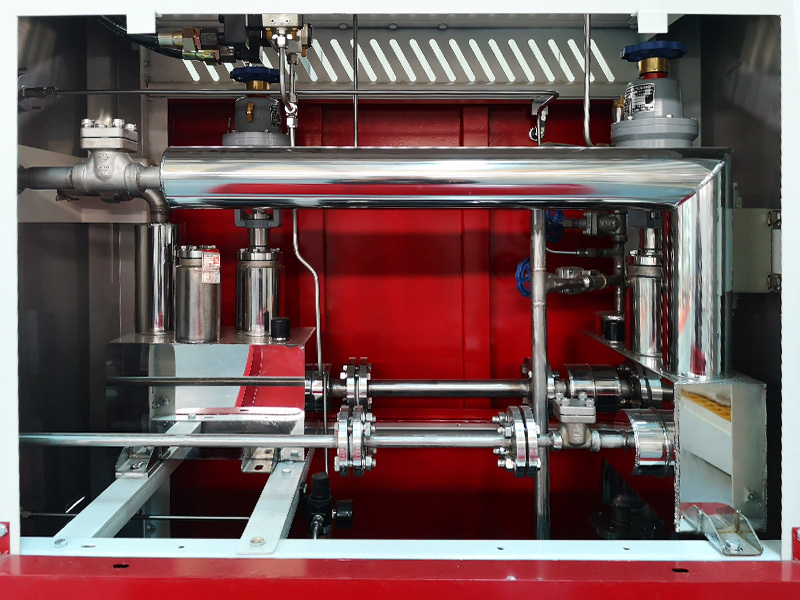

Design

● Structural design: It usually consists of two main parts: the pump body and the prime mover. The pump body includes a hydraulic end and a transmission end. The hydraulic end mainly includes suction valves, discharge valves, pump cylinders and cylinder liners, pistons (plungers), seals, etc. Its function is to compress low-temperature liquids and increase liquid pressure. The function of the transmission end is to input the power of the prime mover through the reduction mechanism, and convert the rotational motion into reciprocating motion through the linkage mechanism.

● Material selection: Due to the transportation of low-temperature liquids, the pump body is usually made of low-temperature resistant materials such as stainless steel to withstand low-temperature environments and ensure strength and toughness. The sealing components are made of materials with good low-temperature performance, such as polytetrafluoroethylene, to ensure good sealing performance at low temperatures and prevent liquid leakage.

● Insulation design: In order to reduce the intrusion of external heat and prevent the vaporization of low-temperature liquids, insulation and cooling measures will be taken for the low-temperature part, such as using high vacuum jacket insulation. Extracting a high vacuum in the middle of the jacket can effectively reduce heat conduction and radiation, and minimize cold loss.

● Safety design: equipped with various safety devices, such as safety valves, which automatically open when the pressure inside the pump exceeds the set value to prevent overpressure; Overcurrent protection device, which cuts off the power supply when the flow rate is abnormal, protecting the pump and pipeline system; There is also a temperature monitoring device that monitors the temperature inside the pump in real time to prevent equipment damage or safety accidents caused by high or low temperatures.

Parameter

The parameters of a low-temperature liquid filling pump usually include the following aspects:

● Working media: liquid oxygen, liquid nitrogen, liquid argon, liquid carbon dioxide, LNG, etc.

● Import pressure: generally around 0.1-0.45MPa.

● Work pressure: usually 15-20MPa.

● Discharge flow range: 100-600L/h.

● Pump speed: 49-490rpm.

● Piston stroke: 28mm.

● Cylinder diameter: Φ36mm。

● Drive power: 5.5Kw, 7.5Kw, etc.

● Motor speed: 125-1250rpm

Hebei Zhengxin Energy Equipment Co., Ltd. is a professional enterprise mainly engaged in the research and development and production of cryogenic equipment and gas equipment. The company has the qualification of pressure pipeline component assembly device (TS27136132027) and pressure pipeline installation (TS3813673-2027), and complies with the international quality management system and has been reviewed by GB/T9001-2016-1S09001:2015 certification and multiple invention patents; the company has been committed to the research and development, design, production, installation, sales and after-sales service of industrial cryogenic equipment and gas transmission and distribution equipment. Our company mainly develops and manufactures: LNG gasification station, gas pressure regulating skid (box), gate station distribution equipment, CNG pressure reducing box (box), low-temperature gasification equipment, LNG filling station equipment, modern workshop centralized gas supply equipment, etc. The company's products are well-known both inside and outside the province for their sound physique, reliable quality, excellent technology and high-quality service. The products are now available in all provinces, cities and autonomous regions in China.

Key words:

Related Products