Categories

Contact Us

E-mail :

hbzx@gasequipment.com.cn

E-mail :

ales@gasequipment.com.cn

Phone/WhatsApp/Wechat:

+86-15810525255

Address:

East of Fenghuang Road, Nangong City, Xingtai City, Hebei Province, China

Steel cylinder filling equipment

We Support Customized Services

Regardless Of Material And Model Please Tell Me Your Needs

- 产品描述

- 符合标准

-

Introduce

1. Gas source system: It is the source of gas, usually composed of gas production equipment or storage containers, such as liquid oxygen tanks, liquid nitrogen tanks, liquid argon tanks, carbon dioxide storage tanks, etc., providing a continuous supply of industrial gas for filling stations.

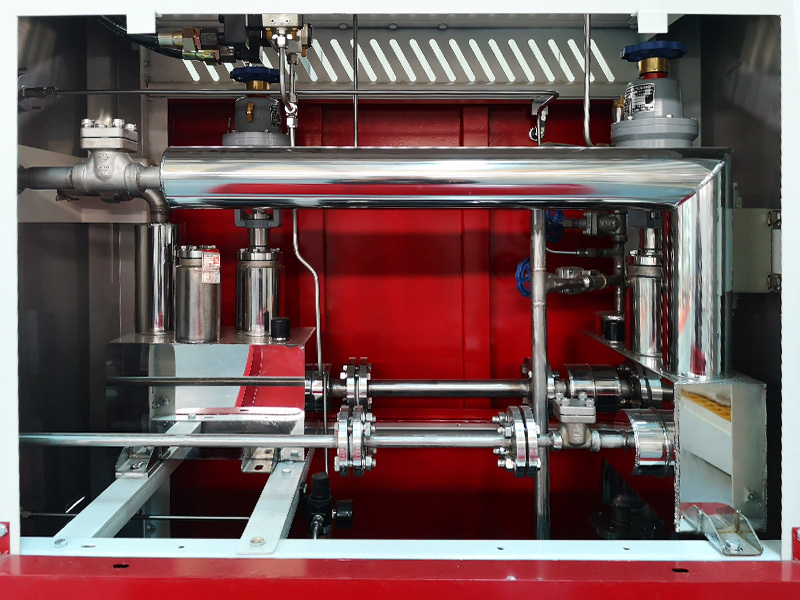

2. Boosting system: A common type is the pneumatic boosting pump, which is used to increase the gas pressure provided by the gas source system to the required filling pressure. Taking the imported pneumatic pump from the United States as an example, it can increase the gas pressure to the maximum installation pressure, and can infinitely adjust the output pressure, and the pressure rise rate can also be freely set.

3. Charging and discharging: including the inflation main circuit and the inflation branch circuit, the inflation main circuit is equipped with a first control valve, the inflation branch circuit is equipped with a second control valve, and the inflation branch circuit is connected to the inflation hose. Its function is to distribute the pressurized gas to various filling stations, achieving simultaneous filling of multiple gas cylinders.

4. Weighing system: Electronic scales are generally used, placed on the filling table, to measure the weight of gas cylinders in real time, accurately control the filling amount, ensure that each gas cylinder can be filled according to the specified weight, and avoid overfilling or underfilling.

5. Limit unit: composed of controller, outer ring, rotating ring, threaded rod, driving component, and limit block. After placing the gas cylinder on the electronic balance of the filling table, the controller activates the driving component to drive the rotating ring to rotate, causing the threaded rod to screw in and driving the limit block to move towards the gas cylinder, thereby limiting different sizes of gas cylinders and improving the applicability of the filling equipment.

6. Lifting mechanism: Installed at the bottom of the inflation table, its output end corresponds to the bottom of the upper surface of the inflation table. By controlling the lifting mechanism through a controller to raise or lower, the bottle mouth of the gas cylinder can be brought closer or farther away from the filling hose, which can adapt to various heights of gas cylinders.

7. Control system: Adopting a two-level control system of computer and PLC, it has the characteristics of stable pressure testing and high pressure testing accuracy. The entire filling process can be completed on a computer, which automatically generates pressure and time curves, stores various data, and can print out test reports at any time. The testing process can also be manually controlled through button switches. In addition, the system also has dual pressure relief devices for automatic and manual pressure relief, as well as overpressure, timeout, and leakage alarm systems, making the entire equipment safer and more reliable.

8. Transport pipelines and valves: used to connect various equipment and transport gases. Pipelines are usually made of stainless steel material to ensure corrosion resistance and safety. Valves include one-way valves, manual valves, pneumatic valves, proportional control valves, etc., used to control the direction, flow rate, and pressure of gas flow. The high-pressure gas valve with modular plug-in design is easy to install, maintain, and upgrade, and can also achieve personalized customization.

9. Filling rack: used to place gas cylinders to be filled, usually designed with multiple workstations, which can simultaneously fill multiple gas cylinders. Some filling racks also have functions such as automatic handling of gas cylinders, grasping of gas cylinders, and automatic opening and closing of cylinder valves, further improving filling efficiency and automation level.

10. Safety protection equipment: including safety valves, rupture discs, pressure gauges, thermometers, combustible gas alarms, oxygen alarms, etc., used to monitor and control pressure, temperature, gas leaks, and other situations during the filling process, ensuring the safe operation of the filling station.

Hebei Zhengxin Energy Equipment Co., Ltd. is a professional enterprise mainly engaged in the research and development and production of cryogenic equipment and gas equipment. The company has the qualification of pressure pipeline component assembly device (TS27136132027) and pressure pipeline installation (TS3813673-2027), and complies with the international quality management system and has been reviewed by GB/T9001-2016-1S09001:2015 certification and multiple invention patents; the company has been committed to the research and development, design, production, installation, sales and after-sales service of industrial cryogenic equipment and gas transmission and distribution equipment. Our company mainly develops and manufactures: LNG gasification station, gas pressure regulating skid (box), gate station distribution equipment, CNG pressure reducing box (box), low-temperature gasification equipment, LNG filling station equipment, modern workshop centralized gas supply equipment, etc. The company's products are well-known both inside and outside the province for their sound physique, reliable quality, excellent technology and high-quality service. The products are now available in all provinces, cities and autonomous regions in China.

Key words:

Related Products