Categories

Contact Us

E-mail :

hbzx@gasequipment.com.cn

E-mail :

ales@gasequipment.com.cn

Phone/WhatsApp/Wechat:

+86-15810525255

Address:

East of Fenghuang Road, Nangong City, Xingtai City, Hebei Province, China

Vaporization pressure regulation ratio pry

We Support Customized Services

Regardless Of Material And Model Please Tell Me Your Needs

- 产品描述

- 符合标准

-

Working principle

● Principle of pressure reduction: Using pressure reducing valves and other equipment, by changing the flow area or using mechanical devices such as springs, the opening of the valve is adjusted based on the feedback of the outlet pressure, thereby reducing the high-pressure gas to the set low-pressure level and ensuring that the gas pressure is stable within the required range. When the inlet pressure changes or the downstream gas consumption changes, the pressure reducing valve can automatically adjust to maintain a constant outlet pressure.

● Principle of vaporization: For liquid gas, it is heated and vaporized through a vaporizer. Common vaporizers include fin type, water bath type, etc. Taking the finned tube as an example, liquid gas flows inside the finned tube, and external environmental heat or heating medium (such as hot water, steam, etc.) is transferred to the liquid gas inside the tube through the fins, causing it to absorb heat and vaporize into a gaseous state.

● Mixing principle: Using mass flow controllers or other flow control devices to accurately measure and control the flow rates of different gases. According to the preset ratio requirements, by adjusting the flow valves of each gas, different gases can enter the mixing chamber in a specific ratio to achieve precise gas ratio. Some advanced systems will also be equipped with gas concentration analyzers to monitor the concentration of the mixed gas in real time, and fine tune the flow rate through feedback control to ensure the accuracy of the ratio.

Design

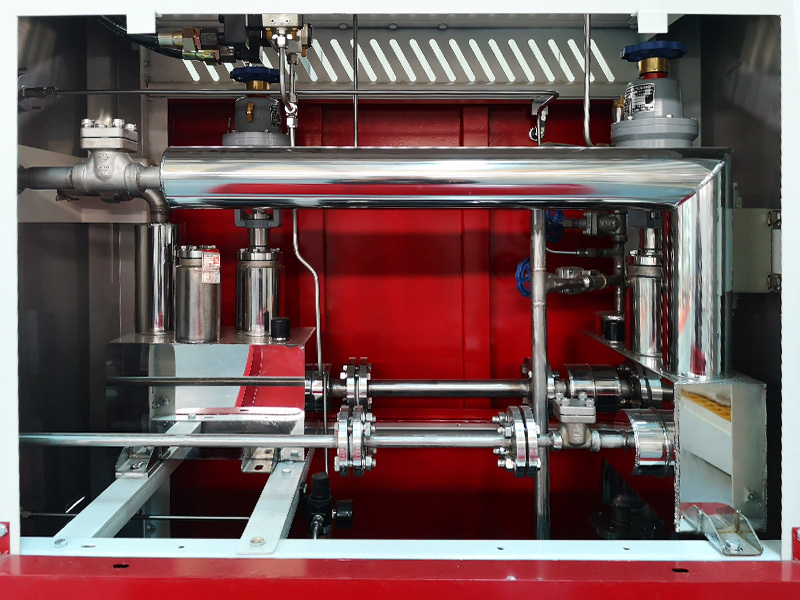

● Structural design: It usually adopts a lever mounted structure, integrating various components on a steel base for easy overall transportation and installation. The pry body usually includes a frame, an outer shell, etc. The frame is welded with steel sections and has sufficient strength and stability; The shell is generally made of metal sheet, which serves the purpose of protection and aesthetics. In terms of internal layout, pressure reducing devices, vaporization devices, proportioning devices, pipelines, valves, instruments, etc. are arranged in sequence according to the process flow. The components are connected by pipelines and fittings, and the layout is compact and reasonable, making it easy to operate and maintain.

● Pipeline design: Select appropriate pipe materials based on the properties, flow rate, pressure, and other parameters of the gas, such as stainless steel pipes, seamless steel pipes, etc. The layout of pipelines should take into account factors such as gas flow direction, resistance loss, thermal expansion and contraction, and reasonably set up fittings such as elbows, tees, and tees to reduce airflow impact and pressure loss. At the same time, necessary support and fixing devices will be installed on the pipeline to prevent pipeline vibration and displacement.

● Control system design: Equipped with advanced control systems such as programmable logic controllers (PLC) or distributed control systems (DCS). Real time monitoring of gas pressure, temperature, flow rate, concentration and other parameters through sensors, and transmitting data to the controller. The controller automatically adjusts the opening of pressure reducing valves, flow valves, and other equipment based on preset parameters and logic, achieving precise control over the pressure reducing, vaporization, and proportioning processes. At the same time, the control system also has an alarm function, which can promptly issue an alarm and take corresponding safety measures when abnormal situations occur.

Parameter

● Pressure reduction parameters: The inlet pressure range is usually determined by the pressure of the gas source, such as 0.6-1.6MPa or even higher; The export pressure can be set according to user needs, generally in different ranges such as 0.02-0.5MPa. The closing pressure usually requires an outlet pressure that is less than or equal to a certain multiple, such as ≤ 1.2P2 (P2 is the outlet pressure).

● Vaporization parameters: Vaporization capacity is a key parameter, which can range from tens of cubic meters per hour to thousands of cubic meters per hour depending on different models and application scenarios, such as 50-5000 Nm ³/h. The design pressure is generally higher than the working pressure to ensure the safety of the equipment, such as 1.6MPa, etc; The work pressure depends on the actual usage situation, such as 0.3-0.7MPa. The imported medium is liquid gas, such as LNG, LPG, etc; The outlet medium is a gaseous corresponding gas, and the outlet temperature is generally required to reach the ambient temperature or set according to process requirements.

● Proportioning parameters: Proportioning accuracy is an important indicator, which can generally reach around ± 1% - ± 5%. High precision systems can achieve ± 0.5% or even higher. The types of gases that can be mixed depend on the design of the equipment, and common combinations include oxygen, nitrogen, argon, carbon dioxide, hydrogen, and other gases. The flow range is determined according to actual needs, and the flow rate of different gases can be adjusted within a certain range to meet different proportioning requirements.

Hebei Zhengxin Energy Equipment Co., Ltd. is a professional enterprise mainly engaged in the research and development and production of cryogenic equipment and gas equipment. The company has the qualification of pressure pipeline component assembly device (TS27136132027) and pressure pipeline installation (TS3813673-2027), and complies with the international quality management system and has been reviewed by GB/T9001-2016-1S09001:2015 certification and multiple invention patents; the company has been committed to the research and development, design, production, installation, sales and after-sales service of industrial cryogenic equipment and gas transmission and distribution equipment. Our company mainly develops and manufactures: LNG gasification station, gas pressure regulating skid (box), gate station distribution equipment, CNG pressure reducing box (box), low-temperature gasification equipment, LNG filling station equipment, modern workshop centralized gas supply equipment, etc. The company's products are well-known both inside and outside the province for their sound physique, reliable quality, excellent technology and high-quality service. The products are now available in all provinces, cities and autonomous regions in China.

Key words:

Related Products