Categories

Contact Us

E-mail :

hbzx@gasequipment.com.cn

E-mail :

ales@gasequipment.com.cn

Phone/WhatsApp/Wechat:

+86-15810525255

Address:

East of Fenghuang Road, Nangong City, Xingtai City, Hebei Province, China

Industrial gas proportioning cabinet

We Support Customized Services

Regardless Of Material And Model Please Tell Me Your Needs

- 产品描述

- 符合标准

-

Introduce

An industrial gas proportioning cabinet is a device used to mix two or more industrial gases in a specific ratio, also known as a gas proportioner, gas mixing cabinet, etc. It is mainly used in conjunction with centralized gas supply busbars and can be widely applied in various occasions that require precise gas mixing, such as railways, ships, chemicals, machinery manufacturing, controlled atmosphere preservation, electric light sources, leak detection (alarm), disinfection and sterilization.

Working principle

Industrial gas proportioning cabinets usually use dynamic gas mixing method, that is, mix and use. The gas that needs to be mixed enters a two-stage or multi-stage pressure balancing device through a one-way valve to balance its input pressure difference and ensure that the pressure of each component gas is the same before mixing. Then, by adjusting the flow control valve, the flow rates of various gases are adjusted according to the set mixing ratio. In the main pipeline, different gases converge in a set proportion to form a uniform mixture of gases. Some advanced proportioning cabinets adopt the mass flow ratio method, which precisely controls the volumetric flow rate of each gas through high-precision mass flow controllers. At the same time, gas concentration analyzers are equipped to monitor the concentration of mixed gases online, achieving more accurate proportioning control.

Design

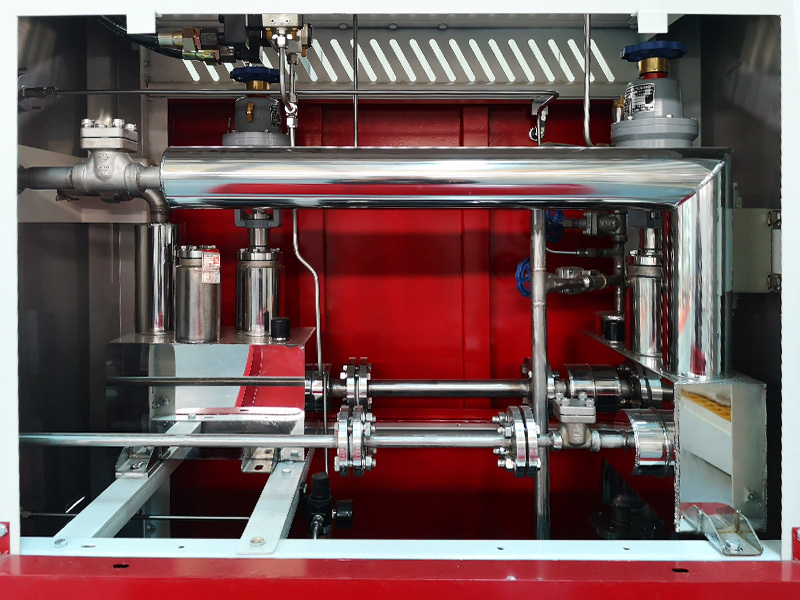

● Structural design: Generally adopts cabinet structure, with compact internal layout. A filter is installed at the gas inlet to filter impurities in the gas and protect subsequent components. The pipelines for different gases are independently set up, equipped with their own pressure regulating valves, gas balance valves, one-way valves, shut-off valves, and gas flow valves. Pipeline materials are usually made of corrosion-resistant materials such as stainless steel to adapt to the properties of different gases. A buffer tank may be installed at the outlet of the mixed gas to ensure a more stable output of the mixed gas.

● Control design: Automatic control. Automatic control adopts programmable logic controller (PLC) and touch screen to display real-time information such as proportioning process, proportioning ratio, working pressure, alarm parameters, etc. Automatic control can also automatically adjust the flow control valve based on the preset ratio and actual detected gas concentration, achieving precise closed-loop control. The system is equipped with remote data control. Real time querying and modifying data on mobile phones or computers.

Parameter

● Types of mixed gases: Common combinations include 0-50% carbon dioxide with remaining argon, 0-50% argon with remaining helium, 0-2% oxygen with remaining argon, and so on.

● Proportion accuracy: Generally, it can reach ± 1.5%, and high-precision proportion cabinets can reach ± 0.05%.

● Flow range: Depending on different models and application scenarios, the mixed gas flow range is usually between 1-10 Nm ³/h to larger flow rates, such as 50-150 m ³/h.

● Input pressure range: It can adapt to different intake pressures, generally within a certain pressure range, such as 0.1-1 MPa, depending on the design and application of the equipment.

● Output pressure: It can be adjusted through a pressure regulating valve to output a stable pressure, usually lower than the input pressure, such as 0.05-0.5 MPa.

● Working temperature: It can usually work normally within the range of -20 ℃ -60 ℃, and can be designed for low or high temperature under special requirements.

Hebei Zhengxin Energy Equipment Co., Ltd. is a professional enterprise mainly engaged in the research and development and production of cryogenic equipment and gas equipment. The company has the qualification of pressure pipeline component assembly device (TS27136132027) and pressure pipeline installation (TS3813673-2027), and complies with the international quality management system and has been reviewed by GB/T9001-2016-1S09001:2015 certification and multiple invention patents; the company has been committed to the research and development, design, production, installation, sales and after-sales service of industrial cryogenic equipment and gas transmission and distribution equipment. Our company mainly develops and manufactures: LNG gasification station, gas pressure regulating skid (box), gate station distribution equipment, CNG pressure reducing box (box), low-temperature gasification equipment, LNG filling station equipment, modern workshop centralized gas supply equipment, etc. The company's products are well-known both inside and outside the province for their sound physique, reliable quality, excellent technology and high-quality service. The products are now available in all provinces, cities and autonomous regions in China.

Key words:

Related Products