Categories

Contact Us

E-mail :

hbzx@gasequipment.com.cn

E-mail :

ales@gasequipment.com.cn

Phone/WhatsApp/Wechat:

+86-15810525255

Address:

East of Fenghuang Road, Nangong City, Xingtai City, Hebei Province, China

Oxygen nitrogen argon carbon dioxide depressurization

We Support Customized Services

Regardless Of Material And Model Please Tell Me Your Needs

- 产品描述

- 符合标准

-

Introduce

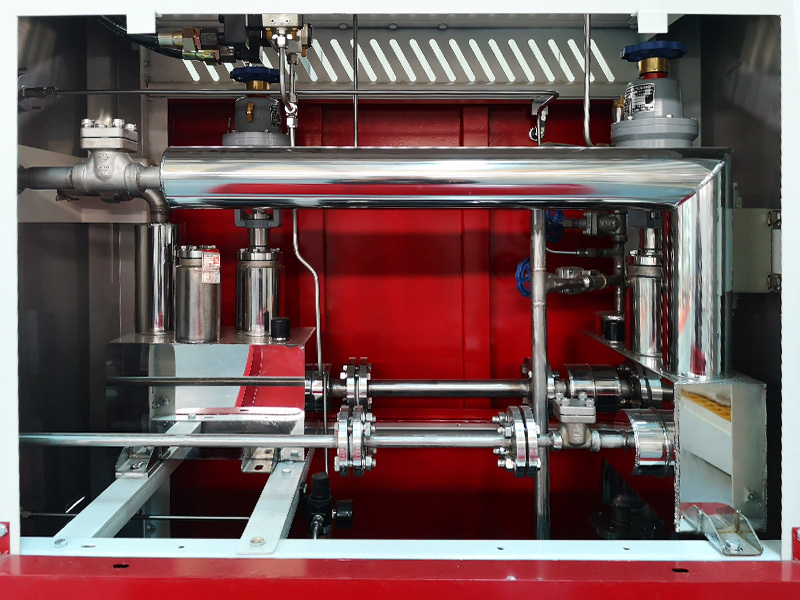

Self standing pressure regulating valve group is a valve combination device that does not require external energy and relies on the pressure changes of the regulated medium itself for automatic regulation. It mainly consists of self operated pressure regulators, filters, safety valves, pressure gauges, globe valves, vent valves, and other components. It can adjust the inlet pressure to the desired outlet pressure and maintain stable outlet pressure, and is widely used in industrial gases, oxygen, nitrogen, argon, carbon dioxide, etc. Pressure regulation systems for gas or liquid media in industries such as petroleum, chemical, gas, metallurgy, and power.

Working principle

The working principle of the self-supporting pressure regulating valve group is based on force balance. Taking the pressure regulating type behind the valve as an example, when the medium flows in from the inlet, it is throttled by the valve core and seat of the self operated regulator to form the pressure behind the valve. The pressure behind the valve is fed back to the actuator of the regulator (such as a diaphragm or piston) through a pressure pipe, generating a force that balances the spring force. When the pressure behind the valve increases, the force acting on the actuator increases, causing the valve core to move in the closing direction, reducing the flow area between the valve core and the valve seat, thereby increasing flow resistance and reducing the pressure behind the valve until it reaches equilibrium with the spring force again; On the contrary, when the pressure behind the valve decreases, the valve core moves in the opening direction, increasing the flow area and raising the pressure behind the valve to the set value.

Design

● Structural design: Usually adopts a pry type structure, integrating various components into one frame for easy installation, transportation, and maintenance. The pipeline connection method often adopts flange connection, which is convenient for installation with upstream and downstream pipelines. At the same time, a bypass pipeline will be set up according to actual usage needs. In the event of a malfunction or maintenance of the regulating valve, the system can be maintained in normal operation through the bypass pipeline.

● Component selection: Self operated regulators are selected based on different pressure regulation ranges, flow requirements, and medium characteristics. Filters are used to filter impurities in the medium, preventing them from entering the regulator and affecting the regulation accuracy and causing valve core wear. Typically, Y-shaped filters or basket filters with appropriate accuracy are selected. The safety valve is used to automatically open and release pressure when the system pressure exceeds the set value, ensuring system safety. Its set pressure is determined based on the maximum working pressure and safety requirements of the system. The pressure gauge is installed before and after the regulator to monitor the inlet and outlet pressure in real time, so that operators can understand the pressure changes in a timely manner.

Parameter

● Import pressure range: refers to the range of import pressure within which the pressure regulating valve group can operate normally, generally ranging from lower pressure (such as 0.1MPa) to higher pressure (such as 10MPa or even higher), depending on the equipment selection and application scenario.

● Export pressure range: It is the pressure range that the pressure regulating valve group can adjust and stabilize the output, usually lower than the inlet pressure. It can be set within a certain range according to user needs, such as 0.01-1MPa, etc.

● Pressure regulation accuracy: Refers to the accuracy of the pressure regulating valve group in regulating the outlet pressure, generally expressed in relative error, such as ± 1%, ± 2%, etc. The higher the accuracy, the more stable the outlet pressure is and the closer it is to the set value.

● Flow range: refers to the flow rate of the medium that the pressure regulating valve group can transport under different pressure conditions, usually measured in cubic meters per hour (m ³/h) or standard cubic meters per hour (Nm ³/h). The flow range ranges from a few tens of cubic meters per hour to several thousand cubic meters per hour, depending on the actual gas or water consumption requirements.

● Working temperature: The temperature range within which the equipment can operate normally, generally between -20 ℃ and 60 ℃. In special circumstances, low or high temperature designs can be made according to user needs.

● Nominal diameter: refers to the inner diameter size of the valve in the pressure regulating valve group, commonly including DN20, DN25, DN40, DN50, DN80, DN100, etc., selected according to the flow requirements of the system and pipeline specifications.

Hebei Zhengxin Energy Equipment Co., Ltd. is a professional enterprise mainly engaged in the research and development and production of cryogenic equipment and gas equipment. The company has the qualification of pressure pipeline component assembly device (TS27136132027) and pressure pipeline installation (TS3813673-2027), and complies with the international quality management system and has been reviewed by GB/T9001-2016-1S09001:2015 certification and multiple invention patents; the company has been committed to the research and development, design, production, installation, sales and after-sales service of industrial cryogenic equipment and gas transmission and distribution equipment. Our company mainly develops and manufactures: LNG gasification station, gas pressure regulating skid (box), gate station distribution equipment, CNG pressure reducing box (box), low-temperature gasification equipment, LNG filling station equipment, modern workshop centralized gas supply equipment, etc. The company's products are well-known both inside and outside the province for their sound physique, reliable quality, excellent technology and high-quality service. The products are now available in all provinces, cities and autonomous regions in China.

Key words:

Related Products