Categories

Contact Us

E-mail :

hbzx@gasequipment.com.cn

E-mail :

ales@gasequipment.com.cn

Phone/WhatsApp/Wechat:

+86-15810525255

Address:

East of Fenghuang Road, Nangong City, Xingtai City, Hebei Province, China

Air heated vaporizer for LNG and liquid industrial gas vaporizers.

We Support Customized Services

Regardless Of Material And Model Please Tell Me Your Needs

- 产品描述

- 符合标准

-

Air Heated Vaporizer for LNG and Liquid Industrial Gas Vaporizers

In the modern industrial landscape, the efficient handling of liquefied gases such as liquefied natural gas (LNG) and other liquid industrial gases is crucial. As industries evolve, the demand for effective vaporization techniques has increased. Among these, air heated vaporizers have emerged as a popular choice due to their operational efficiency and reliability. This article will explore the significance of air heated vaporizers, their working principles, advantages, applications, and considerations for their use in various industrial settings.

Understanding Air Heated Vaporizers

Air heated vaporizers are devices designed to convert liquid gas into its gaseous form by utilizing ambient air as a heating medium. The process begins when the liquid gas is pumped into the vaporizer. As the liquid passes through the unit, it is exposed to heated air, which facilitates the transition from liquid to gas. The temperature of the air is controlled to ensure that the vaporization process is efficient and consistent, allowing for a reliable supply of gaseous fuel or other industrial gases.

These vaporizers are particularly well-suited for LNG and other cryogenic liquids due to their ability to handle low-temperature applications. The efficiency of air heated vaporizers makes them a preferred choice in various industries, including power generation, chemical processing, and gas distribution.

Principles of Operation

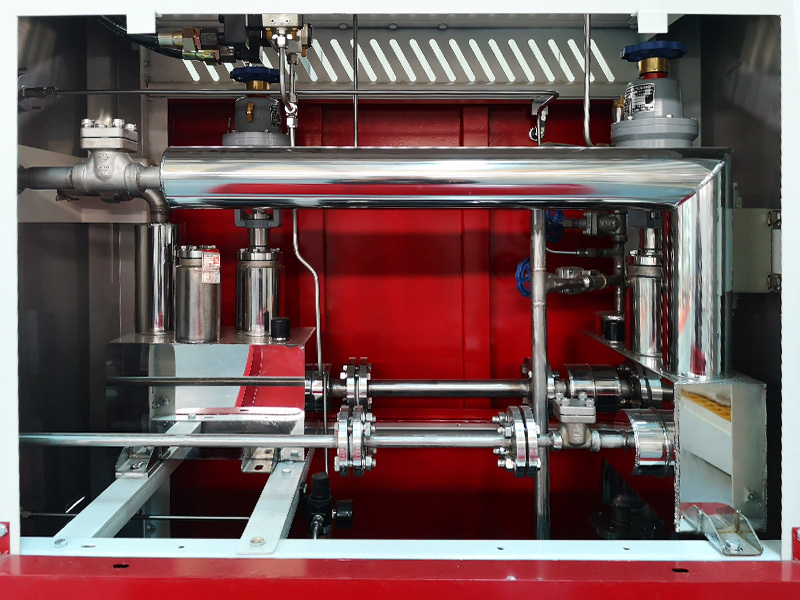

The operation of an air heated vaporizer involves several key components. First, the liquid gas is introduced into the vaporizer through an inlet line. The unit typically contains a heat exchanger where the liquid gas flows through a series of coils or tubes. Surrounding these coils is a flow of heated air, which can be generated through electric heaters or combustion processes.

As the liquid gas passes through the coils, it absorbs heat from the surrounding air. This heat transfer causes the liquid to vaporize, creating a stream of gas that can be directed to various applications. The design of the vaporizer ensures that the heat exchange process is maximized, enabling effective vaporization even in colder climates.

Advantages of Air Heated Vaporizers

Air heated vaporizers offer several advantages that make them an attractive option for industries handling LNG and other liquid gases.

First, they are relatively simple in design and operation. This simplicity translates to lower maintenance costs and easier installation compared to more complex vaporization systems.

Second, air heated vaporizers are highly efficient. They can achieve high rates of vaporization without the need for extensive energy input, making them cost-effective in the long run.

Additionally, these vaporizers are versatile and can be used in various applications, from small-scale operations to large industrial processes. Their ability to handle a wide range of temperatures and pressures adds to their flexibility.

Applications in Industry

The applications of air heated vaporizers are vast. In the energy sector, they are commonly used to vaporize LNG for use in power generation and transportation. As the world moves towards cleaner energy sources, the demand for LNG is expected to rise, further increasing the need for efficient vaporization solutions.

In the chemical processing industry, air heated vaporizers play a crucial role in the production of various chemicals and materials. They facilitate the vaporization of raw materials that are essential for manufacturing processes, ensuring that production remains uninterrupted.

Furthermore, air heated vaporizers are used in gas distribution networks to convert liquid gases into gaseous form for end-user consumption. Their reliability and efficiency make them an integral part of the infrastructure that supports industrial and residential gas supply.

Considerations for Use

While air heated vaporizers offer numerous benefits, there are several considerations that industries must take into account when implementing these systems.

First, the environmental conditions in which the vaporizer operates can significantly impact its performance. Factors such as ambient temperature, humidity, and air quality must be assessed to ensure optimal operation.

Second, the design and sizing of the vaporizer must be appropriate for the specific application. Oversizing or undersizing can lead to inefficiencies and increased operational costs.

Finally, regular maintenance and monitoring are essential to ensure the long-term reliability of air heated vaporizers. Implementing a routine inspection and maintenance schedule can help identify potential issues before they escalate, ensuring continuous operation and minimizing downtime.

Conclusion

Air heated vaporizers represent a vital technology in the efficient handling of LNG and liquid industrial gases. Their ability to effectively convert liquid gas into a usable gaseous form makes them indispensable in various industrial applications. With their advantages in efficiency, simplicity, and versatility, these vaporizers are poised to play a significant role in the future of gas processing and distribution.

As industries continue to evolve and the demand for cleaner energy solutions increases, the importance of reliable vaporization technologies will only grow. By understanding the principles, advantages, and considerations associated with air heated vaporizers, industries can make informed decisions that enhance their operational efficiency and sustainability.

Hebei Zhengxin Energy Equipment Co., Ltd. is a professional enterprise mainly engaged in the research and development and production of cryogenic equipment and gas equipment. The company has the qualification of pressure pipeline component assembly device (TS27136132027) and pressure pipeline installation (TS3813673-2027), and complies with the international quality management system and has been reviewed by GB/T9001-2016-1S09001:2015 certification and multiple invention patents; the company has been committed to the research and development, design, production, installation, sales and after-sales service of industrial cryogenic equipment and gas transmission and distribution equipment. Our company mainly develops and manufactures: LNG gasification station, gas pressure regulating skid (box), gate station distribution equipment, CNG pressure reducing box (box), low-temperature gasification equipment, LNG filling station equipment, modern workshop centralized gas supply equipment, etc. The company's products are well-known both inside and outside the province for their sound physique, reliable quality, excellent technology and high-quality service. The products are now available in all provinces, cities and autonomous regions in China.

Key words:

Related Products