Categories

Contact Us

E-mail :

hbzx@gasequipment.com.cn

E-mail :

ales@gasequipment.com.cn

Phone/WhatsApp/Wechat:

+86-15810525255

Address:

East of Fenghuang Road, Nangong City, Xingtai City, Hebei Province, China

Water bath vaporizer

We Support Customized Services

Regardless Of Material And Model Please Tell Me Your Needs

- 产品描述

- 符合标准

-

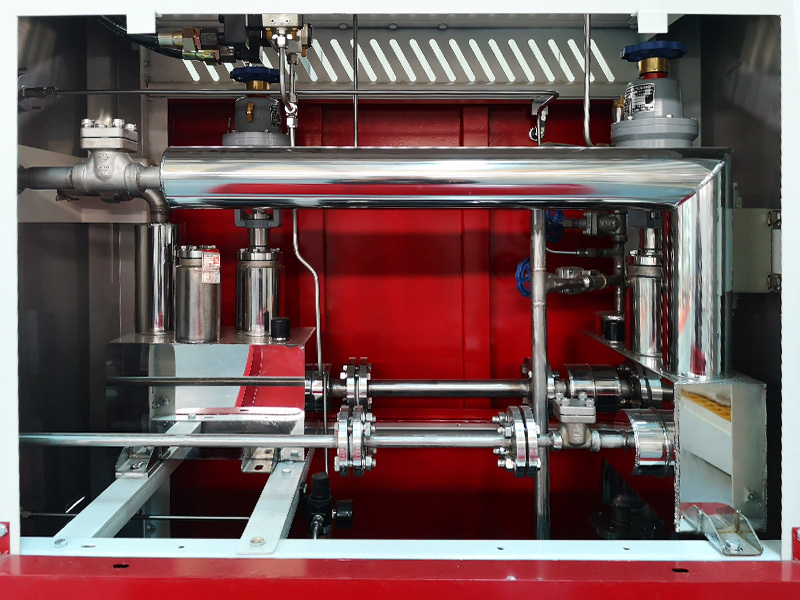

● Structural design: mainly includes large cylinder body, gasification pipeline components, explosion-proof electric heater (electric heating type), and other parts. The top of the large cylinder is equipped with an exhaust valve, water inlet, and liquid level gauge, and the bottom is equipped with a discharge outlet. The gasification pipeline component includes an inlet pipe, an outlet pipe, and several rows of pipes. The two ends of the rows of pipes are respectively connected to the inlet pipe and the outlet pipe. Low temperature gas or liquid enters the rows of pipes through the inlet pipe, exchanges heat with the hot water inside the cylinder, and is discharged from the outlet pipe. To increase the heat exchange area and efficiency, some reheaters are designed with U-shaped heat exchange tubes, inclined tubes, or heat exchange pipelines with torsion spring bending.

● Material selection and design: The large cylinder body is generally made of carbon steel or stainless steel, which has good corrosion resistance and strength. Heat exchange tubes are usually made of high-quality low-temperature seamless stainless steel pipes, such as 304 stainless steel, which can adapt to low-temperature environments and corrosion of different media, and have good heat transfer performance. Explosion proof electric heater (electric heating type) adopts a specially designed high-efficiency explosion-proof type to ensure safe operation in flammable and explosive environments. In addition, some components of the equipment may also be connected by flanges for easy disassembly and maintenance.

● Process design: Based on different application scenarios and media, optimize the flow process of gases or liquids to minimize pressure drop, avoid flow deviation, and ensure that fluid flow rate is controlled within a safe range. At the same time, the heating system and temperature control system should be designed reasonably to meet the user's requirements for the temperature and flow rate of the gas or liquid after reheating. For example, setting the gas pipeline as a staggered and evenly distributed inclined column can keep the outlet temperature constant even when the gas flow rate is high.

Hebei Zhengxin Energy Equipment Co., Ltd. is a professional enterprise mainly engaged in the research and development and production of cryogenic equipment and gas equipment. The company has the qualification of pressure pipeline component assembly device (TS27136132027) and pressure pipeline installation (TS3813673-2027), and complies with the international quality management system and has been reviewed by GB/T9001-2016-1S09001:2015 certification and multiple invention patents; the company has been committed to the research and development, design, production, installation, sales and after-sales service of industrial cryogenic equipment and gas transmission and distribution equipment. Our company mainly develops and manufactures: LNG gasification station, gas pressure regulating skid (box), gate station distribution equipment, CNG pressure reducing box (box), low-temperature gasification equipment, LNG filling station equipment, modern workshop centralized gas supply equipment, etc. The company's products are well-known both inside and outside the province for their sound physique, reliable quality, excellent technology and high-quality service. The products are now available in all provinces, cities and autonomous regions in China.

Key words:

Related Products